WEKO

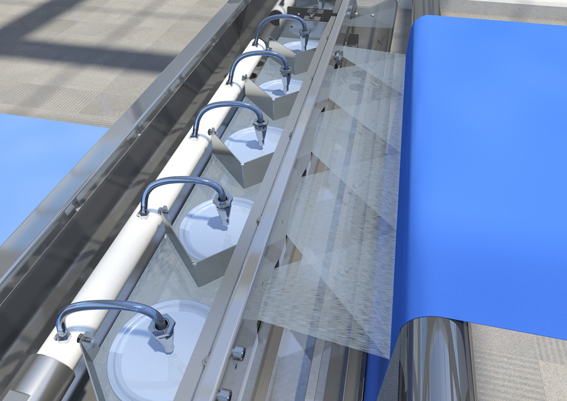

The Weko rotor system is a unique system for applying small to very small amounts of moisture/water and chemicals on material webs. The system is used worldwide in the textile, nonwoven, carpet, (plastic) film, paper, printing and metal industries.

The system works contactless and very accurately over its width and length at various speeds.

In addition to the rotor system, Weko also has a powder system which, like the rotor system, is often used in the printing and film industries.

Weko systems

- Weko-Basic with Weko-Sigma: for contactless application of minimal quantities of water and/or chemicals by means of rotating rotors on textile, nonwoven, carpet, foil and paper.

- Weko-Flow and Weko-Sigma: as Basic-Sigma but with even more control over the entire process. For more high-tech applications.

- Weko-RFS: the system for the (re)moistening of paper.

- Weko-DigiCon: especially for the digital printing industry. Provides paper reconditioning for good flatness, antistatic properties and register accuracy.

- Weko-AP: powder spreading system for the even application of powders on foil, paper, etc.

- Weko-ESC: this system was specially developed for the high requirements of the high-tech machines for engraving, flexo print, film production and special applications.

- Weko-WSA: roller application system for the application of silicones, etc.

- Weko-ProCoat: with WEKO-Fluid-Application-System (WFA) such as the WEKO-ProCoat, paper can be protected reliably against mechanical and physical strain and remoistened at the same time.

- Weko-Clean-It 35: explosion-proof cleaning system for industrial dust. Hoover for dry and wet applications. For use with powder dispensers and other equipment.

Premium Trading Partner

Premium Trading Partner  Over 100 years experience

Over 100 years experience

Tailor-made technical advice

Tailor-made technical advice