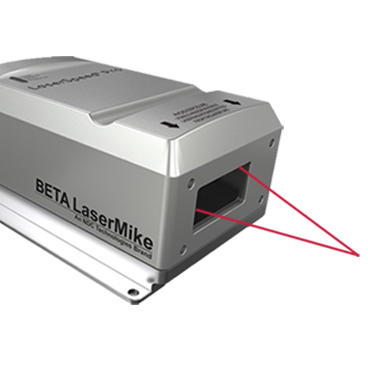

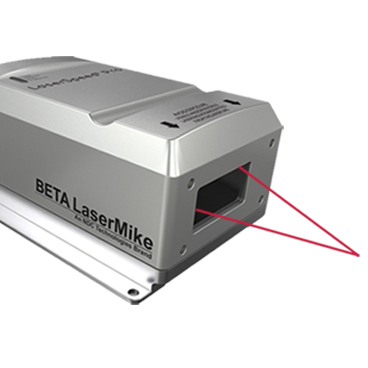

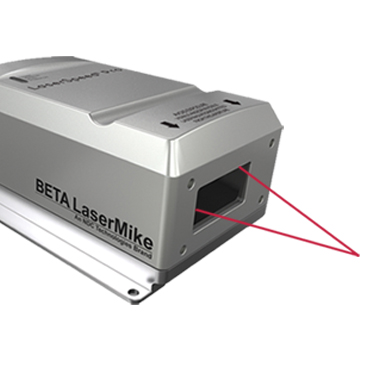

LaserSpeed Pro 9500

Measurement speeds up to 12,000 m/min with unprecedented precision. LaserSpeed Pro 9500 is used for all continuous or discontinuous length measurements. This encoder is based on the proven Laser Doppler Velocimetry principle.

Supplier: BetaLasermike

Premium Trading Partner

Premium Trading Partner  Over 100 years experience

Over 100 years experience

Tailor-made technical advice

Tailor-made technical advice