SHELTON VISION

WebSPECTOR systeem voor oppervlakte inspectie voor diverse industrieën als textiel, automotive, aerospace, composite, nonwoven en medical.

Supplier: SHELTON VISION

We are a consultant for textile and plastic machinery, non-contact sensors for temperature, length, speed, diameter, distance, moisture and shock registration. We also supply the fastest autonomous scalping system.

Premium Trading Partner

Premium Trading Partner  Over 100 years experience

Over 100 years experience  Fastest autonomous fire detection systems

Fastest autonomous fire detection systems

Tailor-made technical advice

Tailor-made technical advice We are the exclusive agent of leading machine manufacturers of textiles, plastics and related industries.

WebSPECTOR systeem voor oppervlakte inspectie voor diverse industrieën als textiel, automotive, aerospace, composite, nonwoven en medical.

Supplier: SHELTON VISION

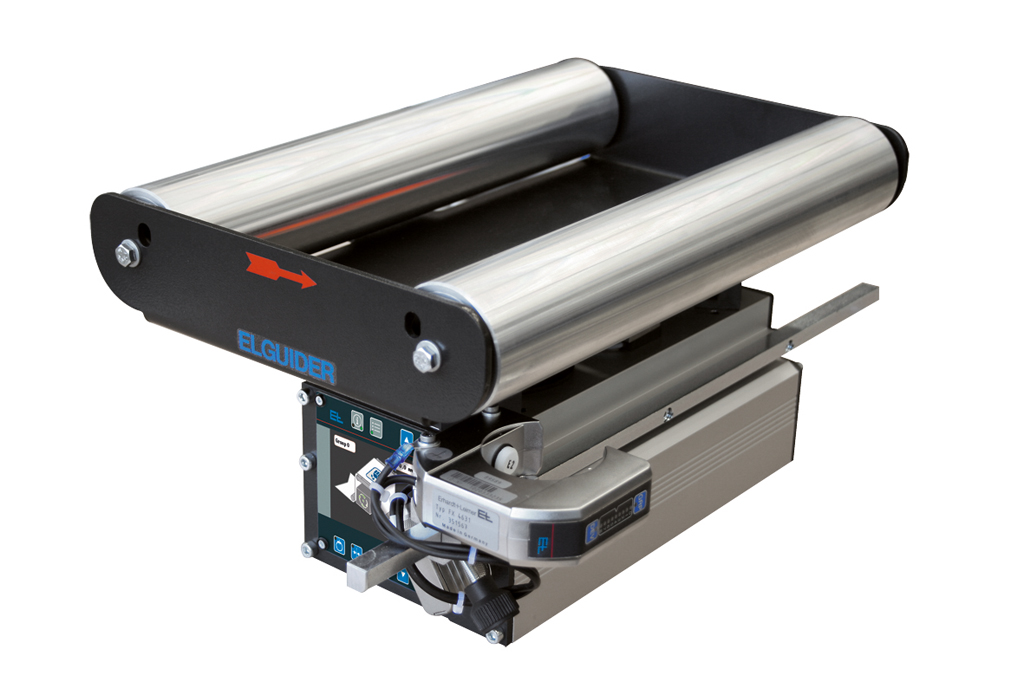

Erhardt+Leimer produces and supplies a variety of high-quality systems for web materials. With the products of E+L you are assured of good web running, the right web tension and you optimise your production process.

Supplier: ERHARDT+LEIMER

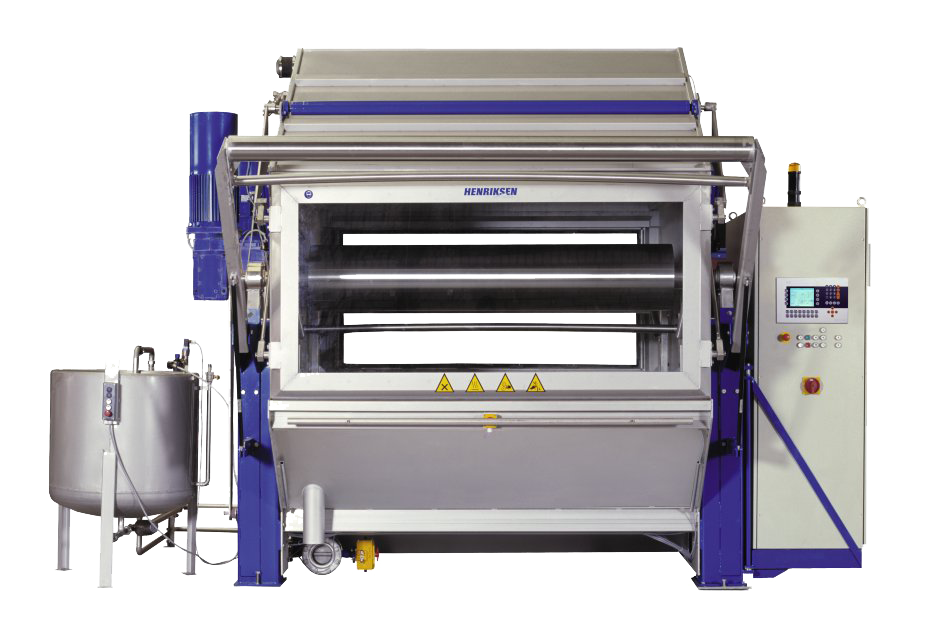

The main applications of the AT Jigger are pretreatment, dyeing and washing of any type of woven cellulose or polyamide fabric.

Henriksen Jiggers are used for pretreatment, washing and dyeing of woven fabrics and are very versatile machines.

All systems are equipped with the unique drive system that accurately maintains fabric tension and monitors both shrinkage and elongation. These features guarantee wrinkle-free operation and accurate sampling.

The advanced process control system for temperatures, chemical dosage, grinding ratio and process time guarantees initial correct processing and full reproducibility.

Supplier: VALD. HENRIKSEN

The main application of the HT Jigger is the dyeing of polyester, polyamides and blends of these fibres with cotton.

The HT Jigger works with temperatures up to 143°C (289°F) and is capable of dyeing synthetic fabrics without environmentally harmful carriers.

Supplier: VALD. HENRIKSEN

Sedo Treepoint supplies various equipment for an almost 100% control of the various dyeing and finishing processes. From machine controls to advanced colour control and test systems. Unique is certainly the Morapex extraction system.

Supplier: SEDO TREEPOINT

Osthoff harvesting machines are the standard in the market. In addition to the warping machines, Osthoff also supplies peripheral equipment such as winders, dedusting systems and impregnation units for pretreatment.

Supplier: OSTHOFF-SENGE

– Vacuum extraction systems for dedusting textile products

– Wet-on-wet finishing solutions

Supplier: OPTIVAC

B.L.W. Visser is, as far as Luwa is concerned, mainly engaged in heat recovery systems for stretchers and other dryers. This Luwa ‘Eco Engineering’ department also supplies air purification systems for dryers. Combined, these installations produce an even better result.

Supplier: LUWA

Corino produces various machines and systems for finishing knits and fabrics. In addition, they have various systems for straightening and pleat-free running of knits, fabrics and nonwovens in production. Call or email for expert advice.

Supplier: CORINO

Brugman’s washing machines for the European market are manufactured in the Netherlands. The requirements of the market are constantly changing. Brugman anticipates this with various innovations. Apart from new machines, Brugman & B.L.W. Visser are also your potential partners for service, parts and/or modernisation of your existing Brugman machines.

Supplier: BRUGMAN HOLLAND

Sohler supplies customer-cut solutions for blowing off and vacuuming dust in spinning and weaving mills. Although Sohler has its famous traversing system, it is custom made for your production.

Supplier: SOHLER NEUENHAUSER

Scholze supplies a wide variety of warp and weft trees. Scholze is able to deliver not only standard sizes, but also smaller numbers of special designs.

Supplier: SCHOLZE