VANWYK SYSTEMS

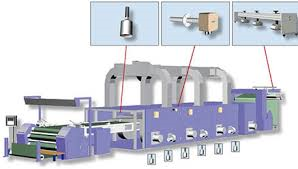

VanWyk Systems develops and produces complete systems for dosing, mixing and conveying liquids and powders for the (textile) dyeing, printing and coating industries.

Supplier: VANWYK SYSTEMS

We are a consultant for textile and plastic machinery, non-contact sensors for temperature, length, speed, diameter, distance, moisture and shock registration. We also supply the fastest autonomous scalping system.

Premium Trading Partner

Premium Trading Partner  Over 100 years experience

Over 100 years experience  Fastest autonomous fire detection systems

Fastest autonomous fire detection systems

Tailor-made technical advice

Tailor-made technical advice Machines and systems for (hotmelt) coating and laminating of textiles, foil, non-woven and composite.

B.L.W. Visser advises you on the right technique for your application and product.

VanWyk Systems develops and produces complete systems for dosing, mixing and conveying liquids and powders for the (textile) dyeing, printing and coating industries.

Supplier: VANWYK SYSTEMS

Pleva produces sensors and (control) systems for measuring the various parameters in drying and coating processes for the textile, carpet, nonwoven, paper and related industries.

Measuring and controlling the different parameters improves the drying process and the quality of your product. Also the reproducibility and energy consumption can be optimised.

Supplier: PLEVA

Sensors for measuring the moisture content of materials during e.g. impregnation, painting, coating and drying. Perfect application for efficiency measurement in water-based processes.

Supplier: PLEVA

Sensors for measuring material and air temperature in drying processes. Sensors to be used in drying processes up to 400°C, without cooling.

Supplier: PLEVA

PLEVA FSX sensor for on-line measurement of the humidity of the air to be exhausted from dryers and clamping units.

The FS sensor ensures an optimal drying process and prevents emission of unused energy.

Supplier: PLEVA

The Pleva StraightLiner SL 1 & SL 2.1 are impact straighteners where the full width (every 5 cm!) is detected by a CCD camera. As a result, this system is not only much faster and more accurate than other systems on the market, but it also provides information about the exact width and weft density or number of stitches per cm. of the fabric/knit.

Supplier: PLEVA

The two pillars of MATHIS AG

1. Building laboratory textile machines for dyeing and finishing applications in the textile, chemical and paint industries. Today we are proud to say that we are the world’s largest manufacturer of laboratory textile machines.

2. Construction of coating systems for laboratories and production facilities in the textile, paper and film industries, the pharmaceutical and plastics industries, battery and fuel cell producers, steel and aluminium processors and the automotive industry.

Supplier: MATHIS

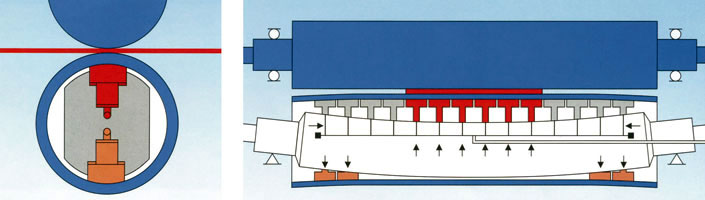

Guarneri Technology is the only manufacturer of calendaring systems offering deflection-controlled NIPCOr rollers for textile finishing and technical textiles. This calendar technology is characterised by decisive design advantages such as:

– Stationary shaft and turned sleeves

– Freely rotating sleeves: Polyamide PGT6, TopTech 3r, Paper, Cotton or Steel

– Motorised width adjustment for different fabric widths

– Multiple surface pressure adjustment with a wide spread over the entire working width

– Sleeve retraction to prevent edges from overheating

– Step less adjustment of the area pressure from 25 – 400 N/mm

– Maintenance-free Electrothermal hot water system for the steel coil

– Alternative heating systems on request, such as thermal oil or gas

– Peripheral steel coils for fast response to temperature regulation or resetting under high speed

Supplier: GUARNERI TECHNOLOGY